Loading... Please wait...

Loading... Please wait...- Contact

- wiggys@wiggys.com

- Home

- News + Commentary

- the good thing is still very available from Wiggy's.

Recent Commentary

News & Commentary Archives

Learn More

Subscribe to Wiggy's Newsletter » Receive updates about new products, specials, and learn about insulation technology

the good thing is still very available from Wiggy's.

Posted on Oct 24th, 2019

THEY DON’T KNOW A GOOD THING WHEN THEY HAVE IT!!!

I keep exposing the folly of all of the U.S. Army’s testing laboratory for insulation. As I have reported the continuous filament fiber was first exposed as a finished product to the outerwear and sleeping bag industry in 1968. The military was the original reason that Celanese Corporation developed the machine that took the continuous filament band of fibers that is made up of 200,000 filaments and opened and spread into the batting that I receive and convert to Lamilite. When it was first produced it was not laminated as I do but quilted and it was used for mittens, field jacket liners and sleeping bags, this business lasted about 10 or possibly 12 years. The military never had a problem in all that time.

The continuous filament fiberfill product was also sold to the manufacturers that sold sleeping bags and outerwear mostly and it was called Polar Guard. Back then the military would never name a product regardless how much of it they used. Today they unfortunately name goretex and a few other brands against I believe policy. Big deal. But they never name Climashield I believe, they just say continuous filament fiberfill.

It was when developed or invented the best insulating medium ever developed. But the employed unknowledgeable about insulations at the Army’s testing laboratory weren’t around back then so they were easily convinced by charlatans that they had the best. They even caused the Army to fork out in a research program $700,000.00 to Albany International to develop “an alternative to down” which was a polyester batting no different than what already existed sine the early 1960's. They called their product primaloft. It did not then nor does it today have loft unless you compare it to a sheet of paper.

These people who function in the testing of insulations area when exposed to continuous filament fiberfill did not know about it because they had no background in insulations and did not understand how efficient the product is and they further could not understand that this product did not need to be quilted. Lamination they were told was the best way for a manufacturer to use it in production by me. This is a concept that flew over their heads as fast as an SR71 could fly.

When it was explained to them eliminating the stitching you eliminated cold spots and therefore the product, sleeping bag or jacket would perform better, this was a concept that they also could not fathom.

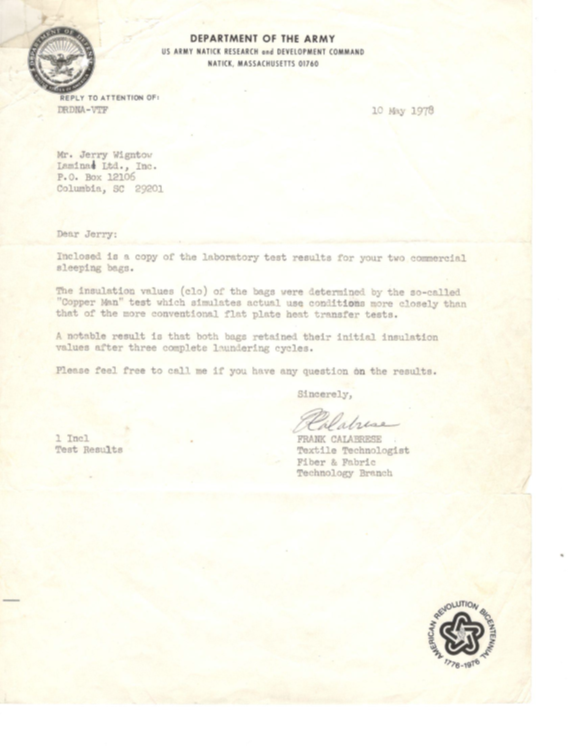

I could go on and on like Texas but I will not. At this point I will mention the two pages that follow, a report sent to me from the textile technologist employed by Natick at the time after he tested two bags, I sent that were ultimately the Wiggy’s Super Light and Ultima Thule models. Aside from the testing for insulation capability which is represented in “clo”, I did ask for a Fahrenheit number but he said he couldn’t give me that because he could not convert “clo” to F. The reality no one can! Any way what he was impressed with the samples I sent to him was the fact that after three complete launderings the bags retained their insulation value actually the numbers after laundering were higher.. Imagine that, that is why I am so much in favor of Wiggy bag buyers laundering their Wiggy’s bags.

The problem we taxpayers have is simple; employees that don’t research what has happened before them. I am sure this letter to me is on file. Years later I sold them a current Ultima Thule and they tested it on their copper man and the “clo” value was above 10. That is a number they have never seen before.

Like I said in the title; ‘THEY DON’T KNOW A GOOD THING WHEN THEY HAVE IT”!!!

I rest my case.

The letter is below the shows the test results, note the "clo" value increased after laundering.